This is a service in March, and Jack has been too busy lately to update it until today😓

let’s start…

Unintentional Contact

The customer contacted us in February and expressed their willingness to purchase some kitchen tap extenders. The customer has listed several suppliers and hopes that we can help conduct a background check.

Because the customer only requested confirmation of whether they are traders or a factories, it didn’t take too much time, so we helped the customer complete it for free.

At that time, we thought it was just a simple consultation, and after telling the customer the answer, we ended the conversation.

Second Contact

March is a busy month.

SourcingBiz had too much work, and some customers were coming to China for an exhibition in March & April.

One day, this Indian customer suddenly sent us a message saying that they had submitted an order in February and after one month of production, the factory had already finished production.

The customer is working with this supplier for the first time and is a bit concerned about the product quality. They hope to have an inspection conducted before shipment.

The customer wishes to entrust this task to SourcingBiz.

Because this supplier is only 50 kilometers away from SourcingBiz, which is relatively close, we agreed it.

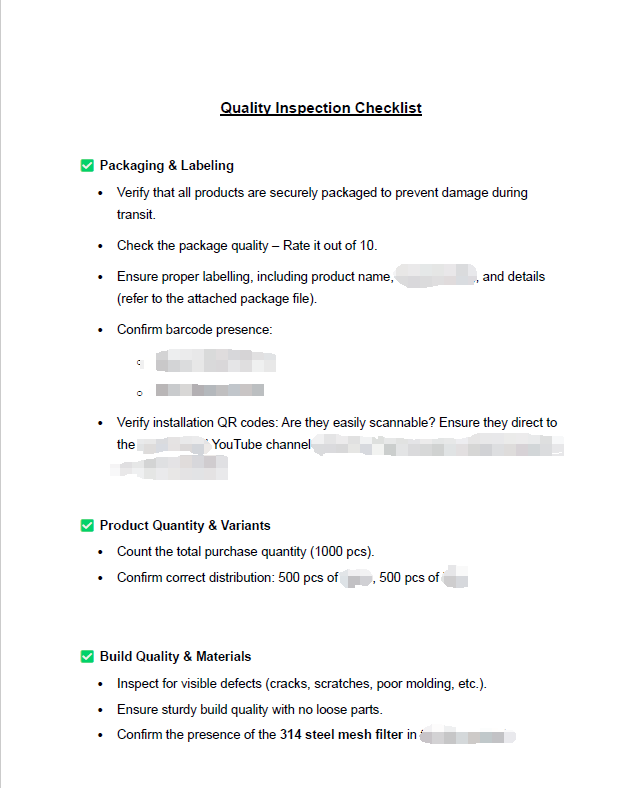

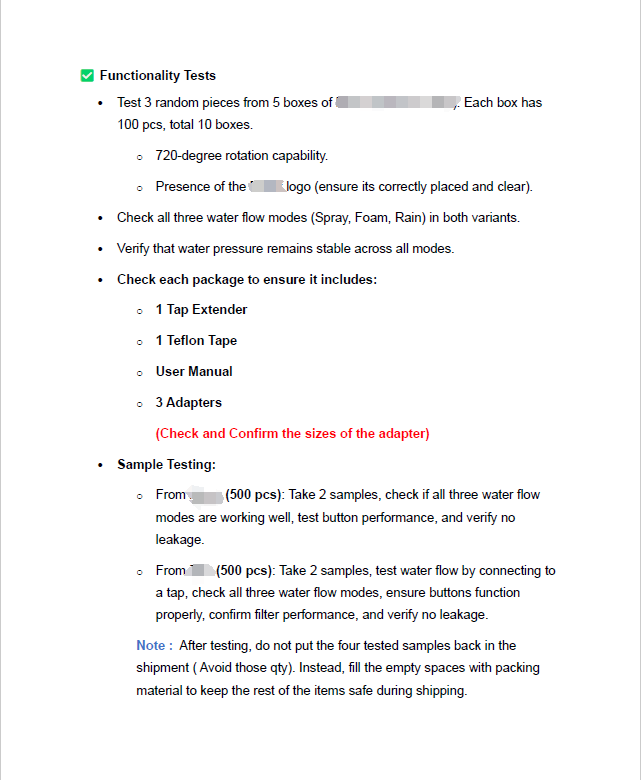

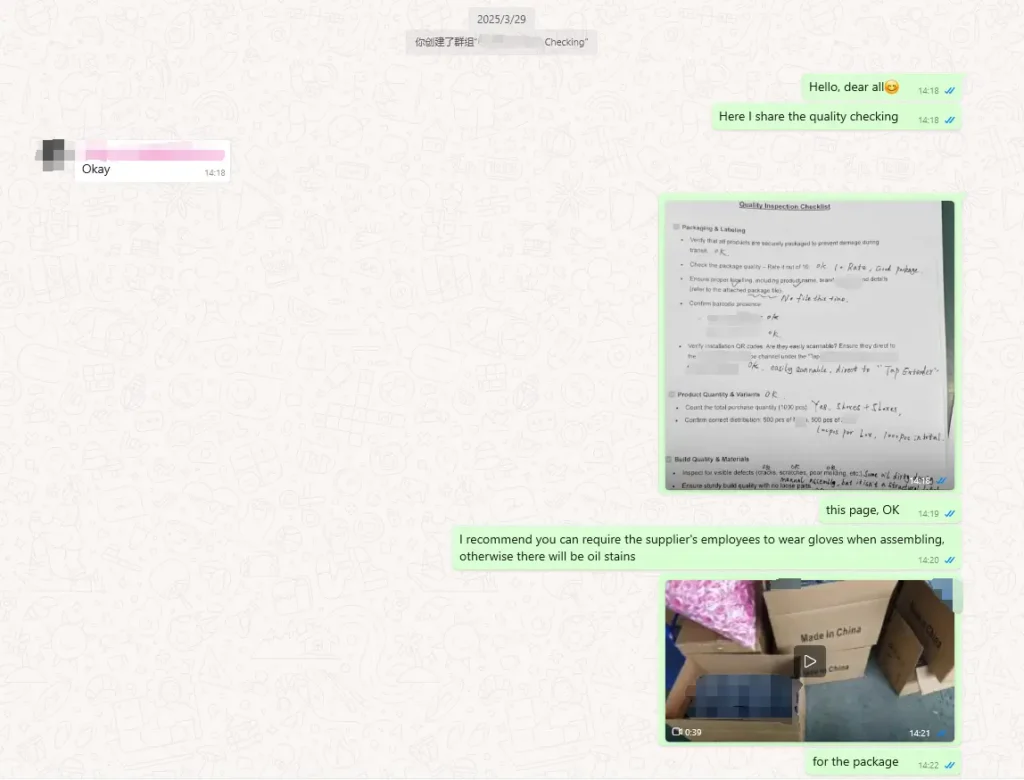

Quality Inspection Checklist

As we know, different products, buyers, and sales channels have different quality inspection requirements.

So, based on our own experience and combined with the customer’s needs, we had a communication and compiled a list of quality inspection contents.

Starting Work

After confirming the customer’s requirements, Jack drove to the supplier’s factory.

An hour later, Jack arrived. It is a small factory.

Before the visit, Jack had already communicated the itinerary plan with the factory in advance, so it went smoothly. Jack directly started the product inspection.

At the same time, Jack also reported the on-site situation to the Indian client in real-time.

Problem Arises

According to the checklist, we confirm the quality item by item.

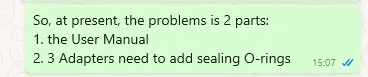

Jack discovered two issues in total.

One product miss the user manual.

The most serious is, one series’ adapters missed a black sealing ring. According to the design requirements, a total of three sealing rings are needed, but only two pieces inside.

We informed the factory and customers of the results, and the factory repackaged the missing parts into the product, avoiding a risk once.

Happy Ending

Besides, Jack obtained the business license and certification information of this factory and shared it with the India customer.

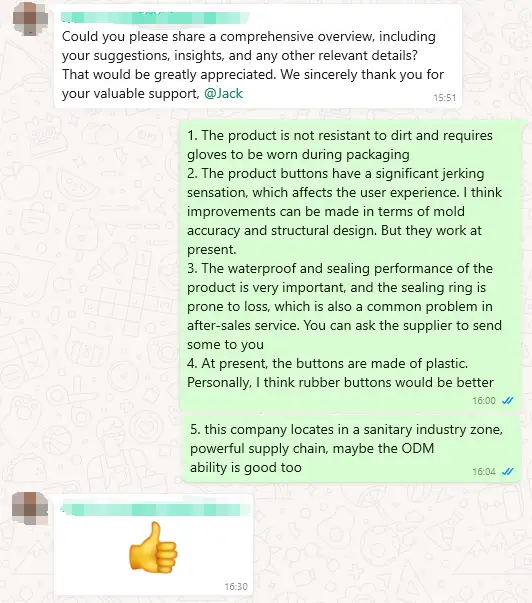

The Indian customer sought Jack’s suggestions.

Finally, after a day of work, all the problems were resolved.

Jack began to return.

Customer‘s Feedback

In the evening, Jack returned home smoothly.

Collaboration is still ongoing!